HDPE Composite Jacketing

PileClad/PlasClad HDPE Composite Jacketing

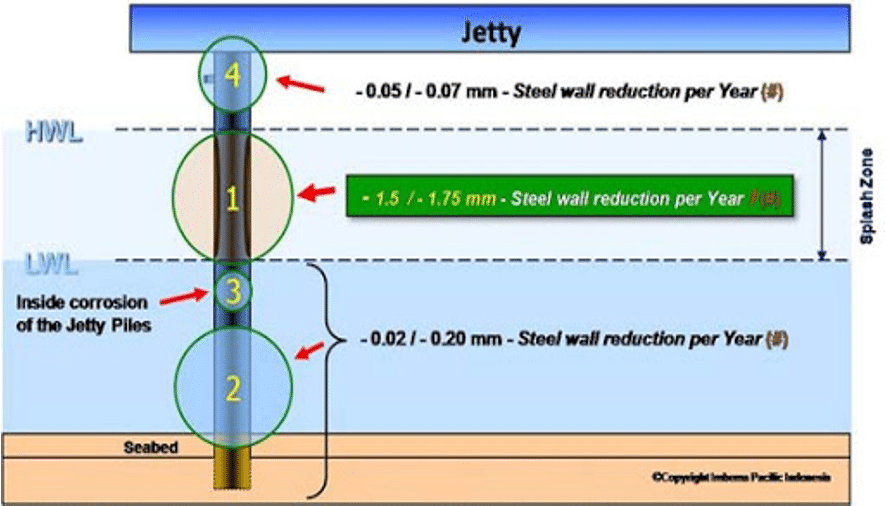

New jetty construction will undergo deterioration over time. Hence, all the piles need to be protected so that the rate of corrosion can be delayed. Especially in the splash zone the rate of corrosion can cause up to 3.0 mm or more steel wall reduction. HDPE Jacketing has been the solution for protecting steel piles over the years. However, the old system of HDPE jacketing still uses petrolatum tape as an anti corrosion agent, yet in many of the cases over the years it causes sagging of the HDPE jacket.

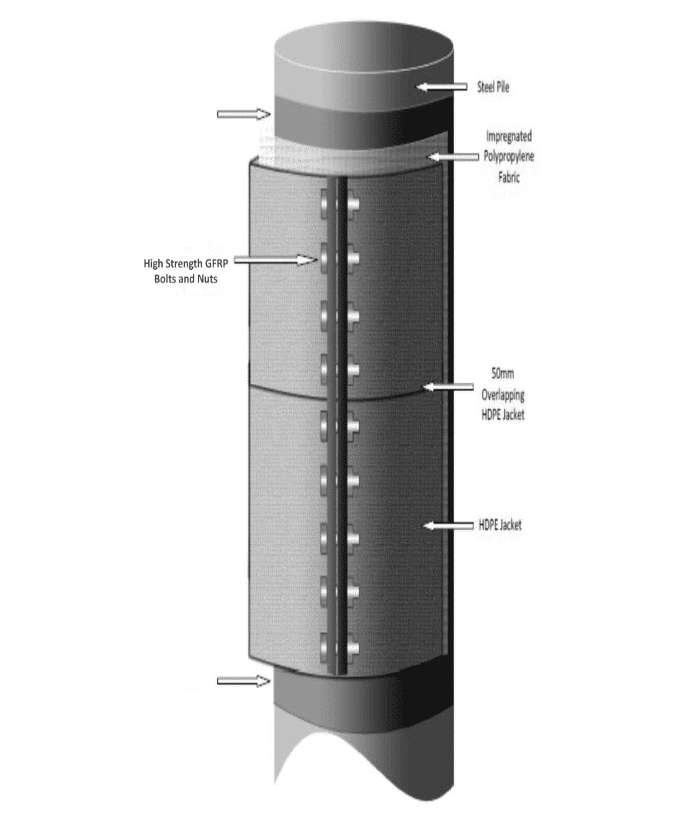

So PT BMJP has come up with a new system of HDPE Composite systems called PileClad/PlasClad. It has a totally different concept with the old Conventional HDPE jacketing system that uses petrolatum tape and Stainless Steel Bolts and Nuts.Its become loosen & fall down , hence continue Unprotected and Corroded

What is PILECLAD/PLASCLAD?

A specially designed clamped-on (GFRP Bolts) HDPE composite jacket attached with underwater epoxy to piles and pipes for maximum protection against corrosion, marine growth,and impact under extreme exposure.

HDPE Jacketing

Works:

Power Tool Cleaning (SSPC-SP 3)

➥ Primer Coat : BMJP Curable underwater CUE Epoxy

➥Materials : PileClad/PlasClad 2.0 -3.0 mm

PT. Baria Bulk Terminal

2020