Vapour Blasting

Vapour Blasting

(Spark Free Blasting Technologies)

Pipelines operate in some of the most severe environmental conditions, to slow down the decrease in strength and function of a pipeline, therefore it is necessary to protect by protective coatings. A protective coating is a layer applied to the surface of concrete, iron or steel which has the function of avoiding direct contact with air, liquids, harsh chemical substances and other substances that can cause corrosion. protective coating not only prevents water penetration but also has the function of preventing damage to concrete, pipes or steel.

- Ideal for coating removal, surface preparation, restoration, industrial cleaning, concrete repair and much more!

- Maximum blast performance - Minimal dust

- Up to 92% less dust than traditional dry blasting

- Uses less water than slurry and traditional water blasting technologies

- ATEX approval for using in hazard area

- Higher performance than same specifications Dry blaster

- A cleaner, easier path to profitable results

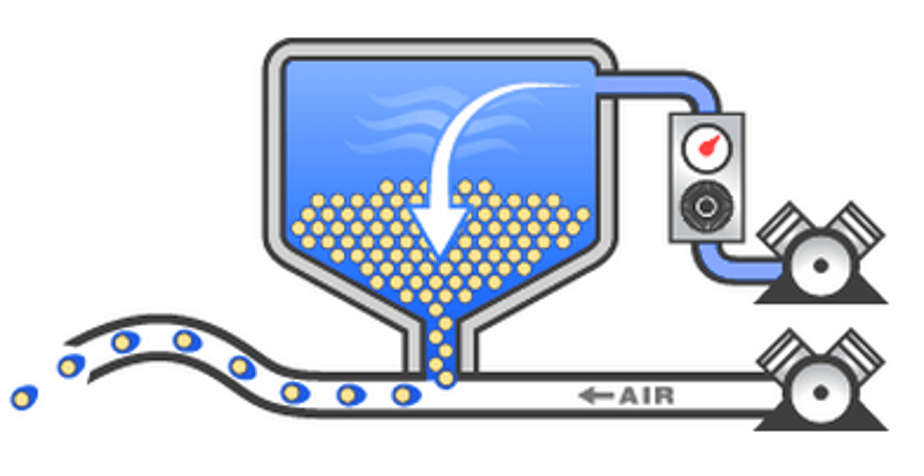

How Vapour Blast works?

- Water and abrasive are combined in a pot under water pressure, then injected into the airflow. Pot pressurized by water.

- Affords fine control over the air pressure and water/abrasive mixture, allowing for blasting of a wider range of surfaces and reducing the amount of media and water expended.

Works:

customer review

Designation

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Designation

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Designation

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.